PHYSICAL TRANSFORMATION PLANT

TIS NUTRA

High-efficiency ingredients

PHYSICAL TRANSFORMATION PLANT

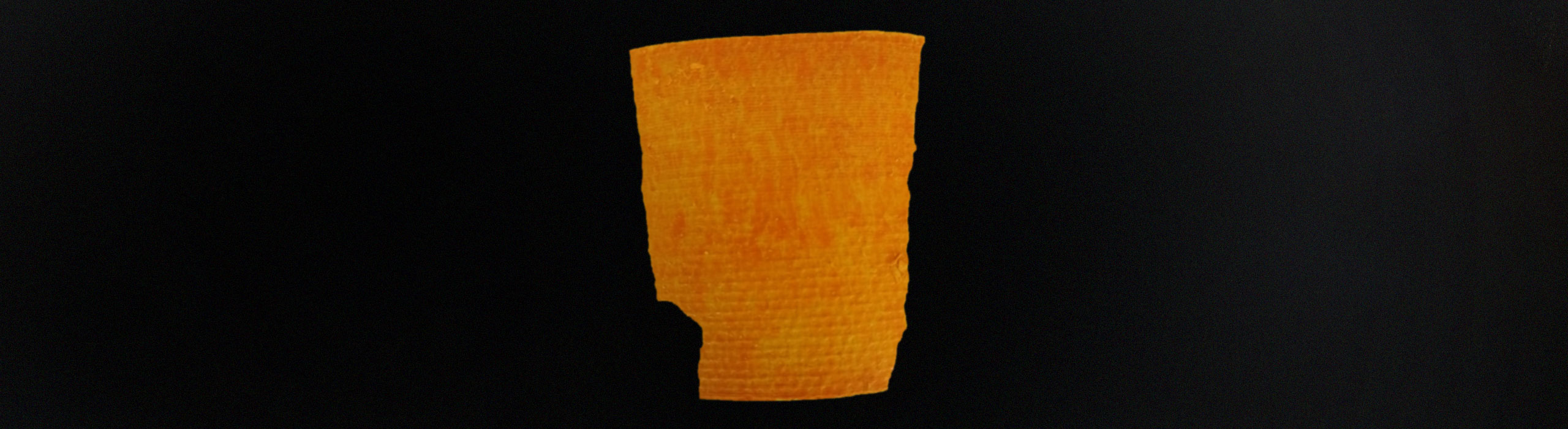

Compaction and Granulation of actives in Hipering Technology

PHYSICAL TRANSFORMATION PLANT

High quality standards